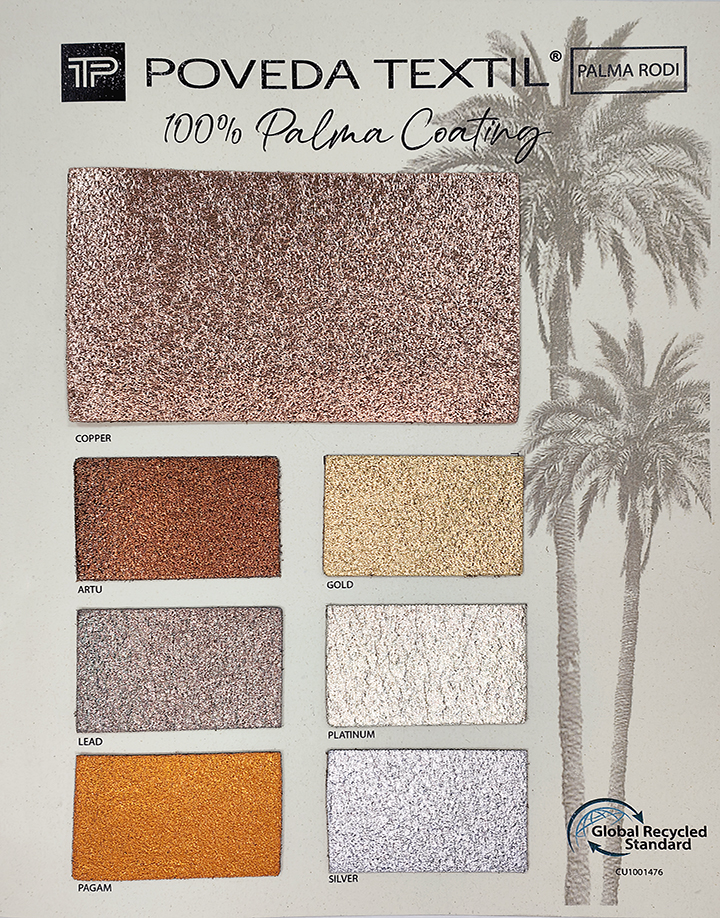

Fabric made of palm trees from Alicante

Palm Collection

Fabric made of palm trees from Alicante

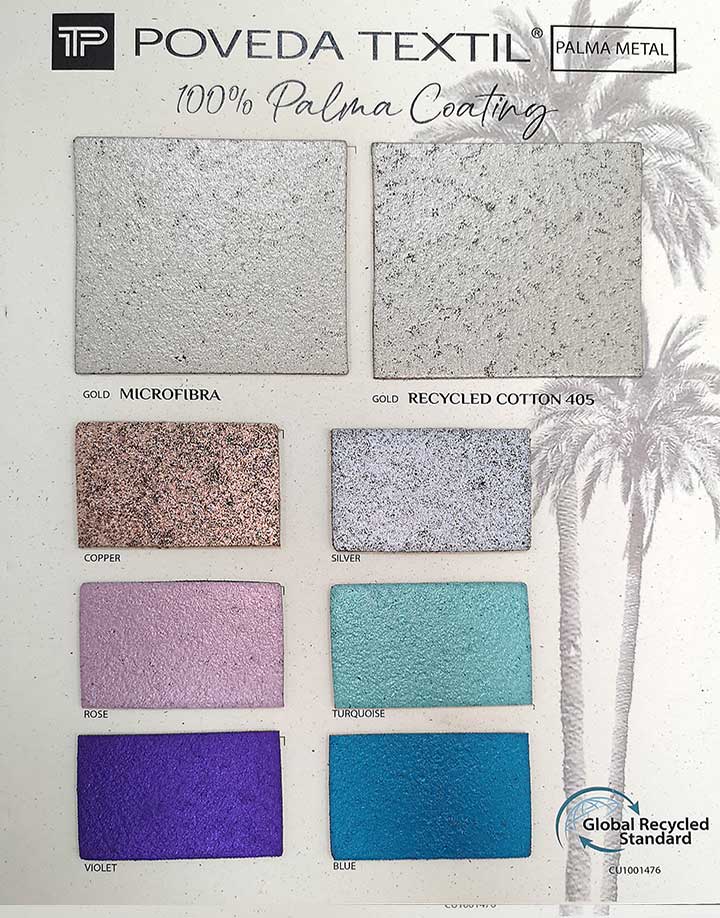

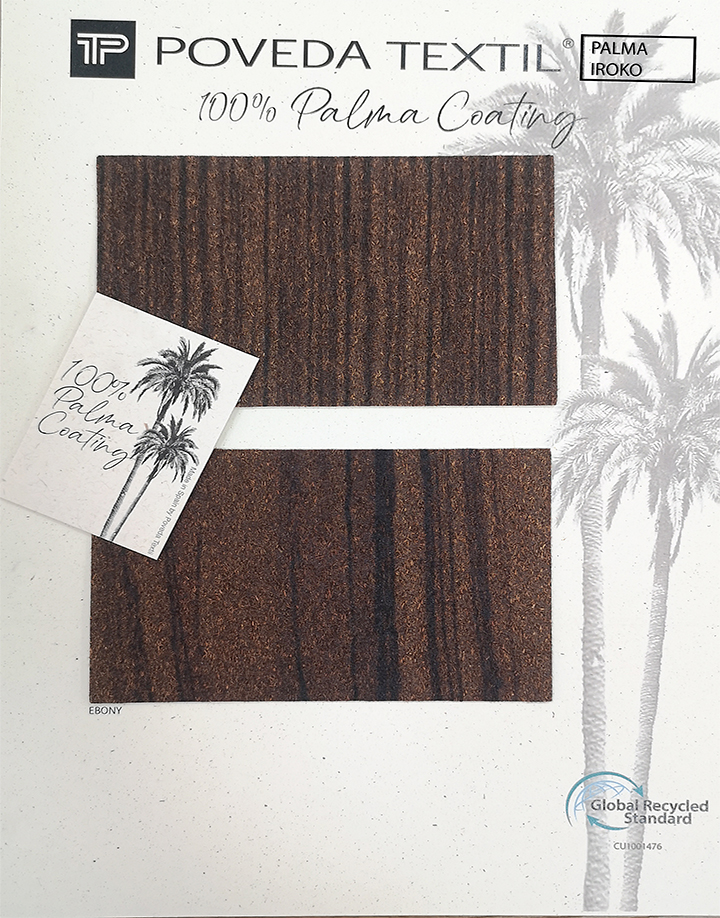

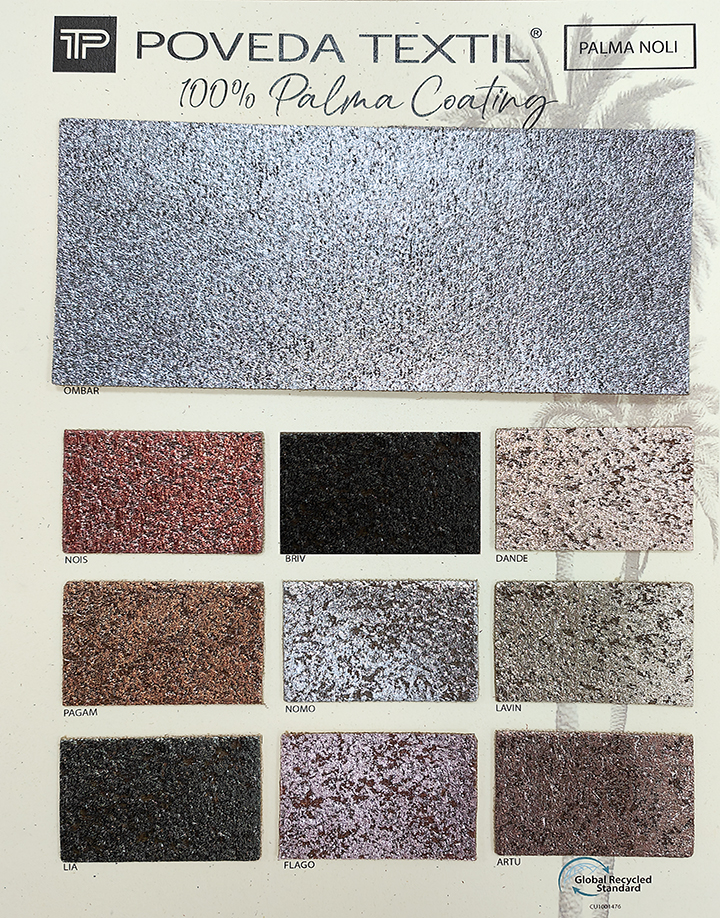

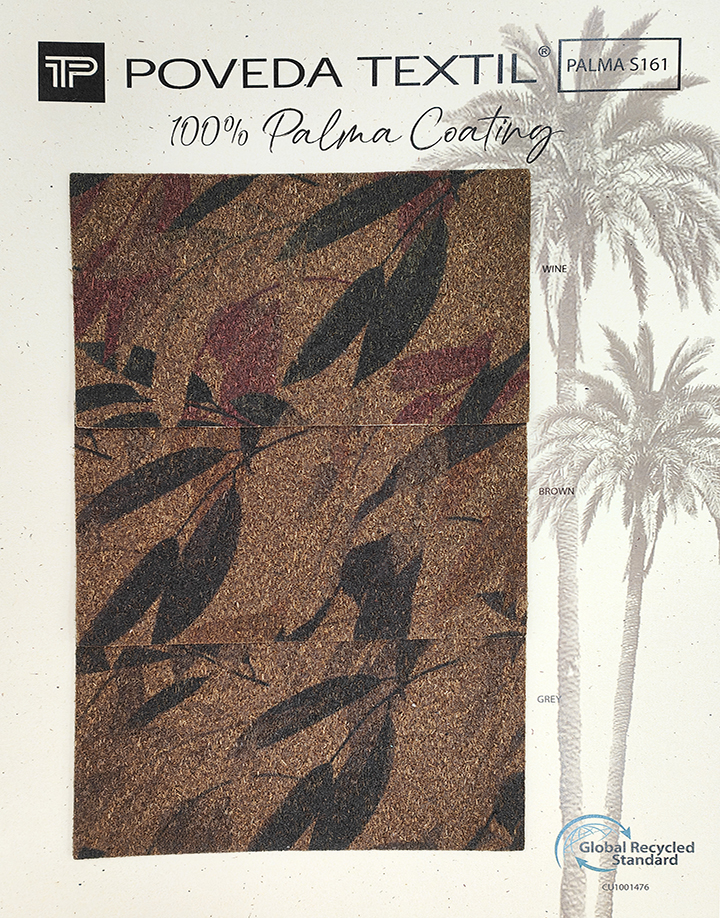

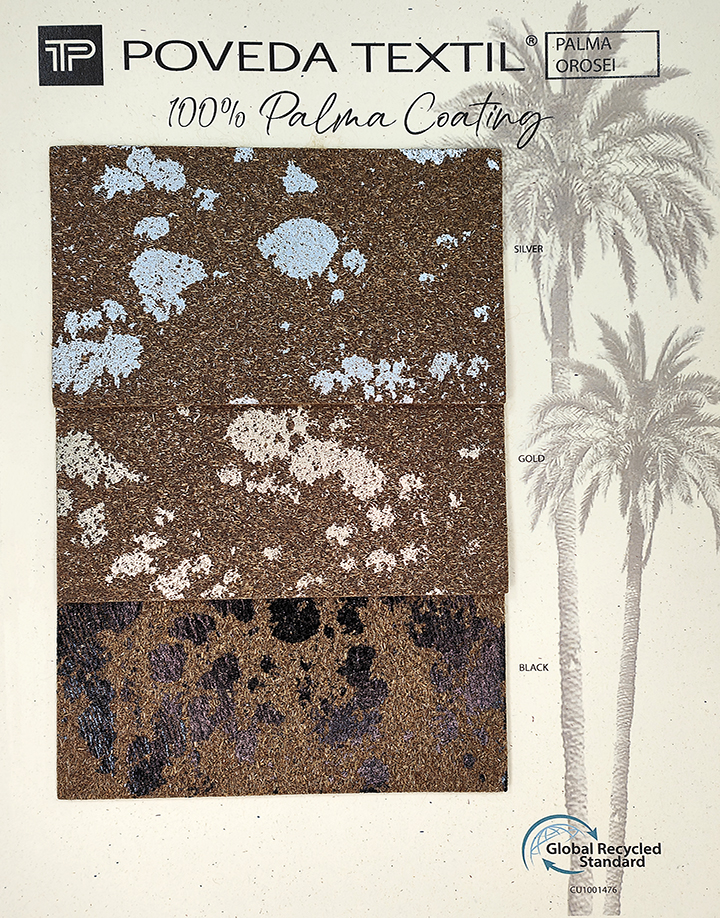

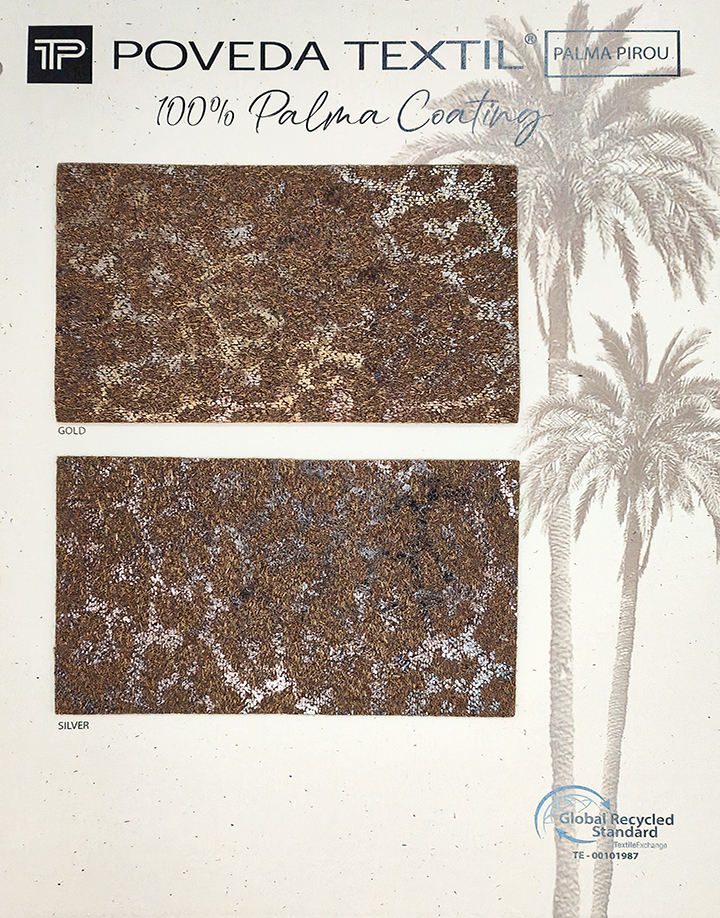

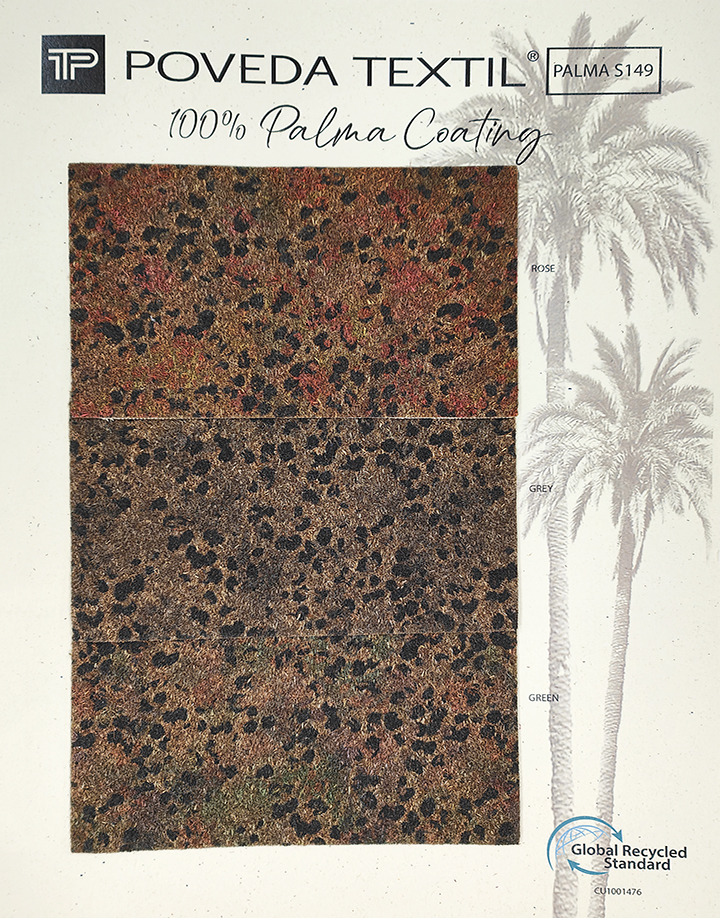

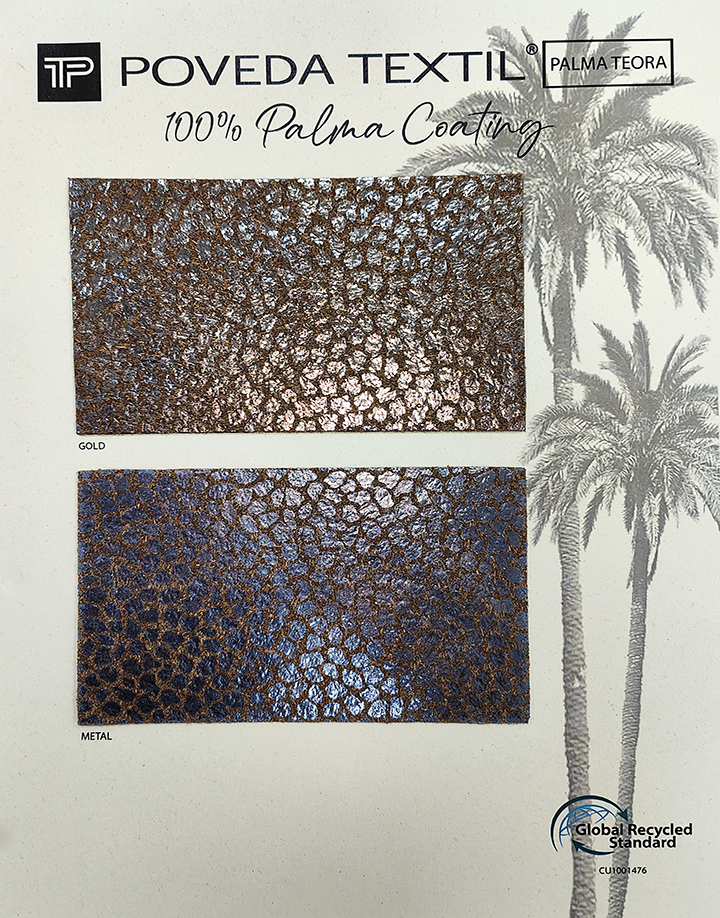

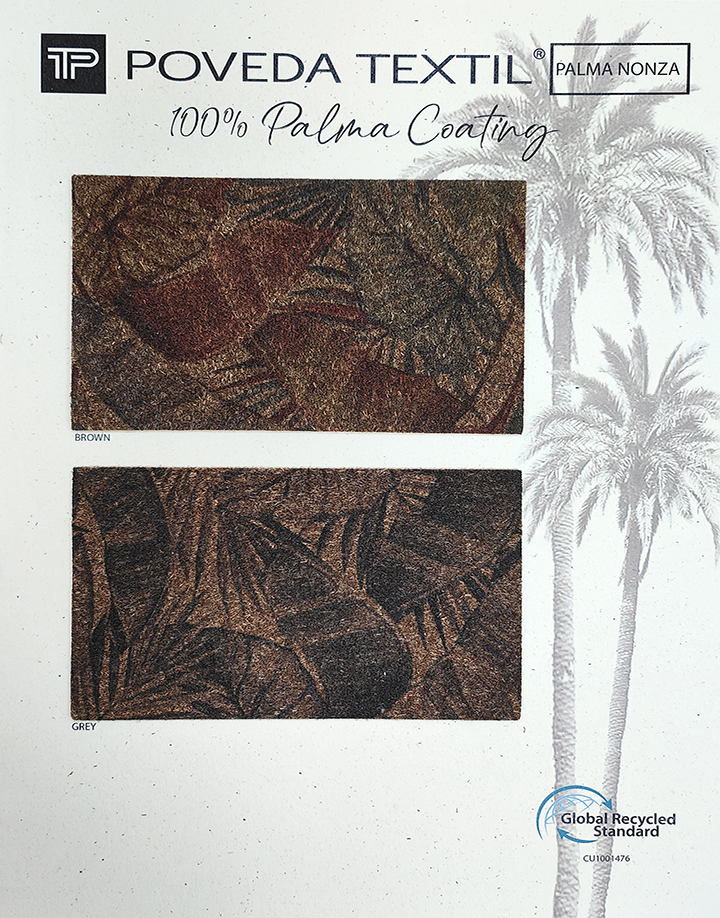

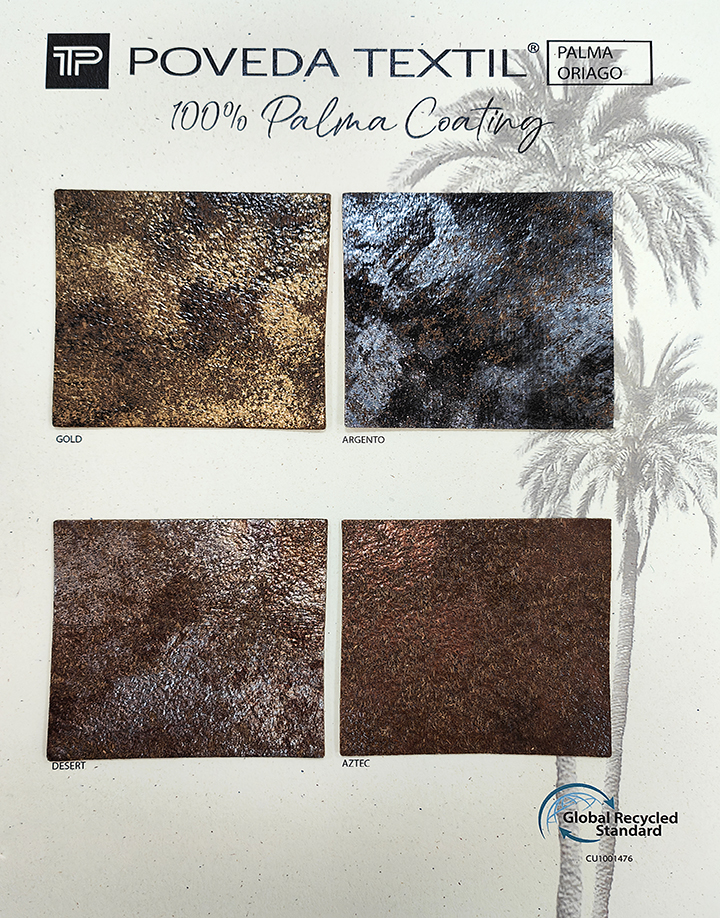

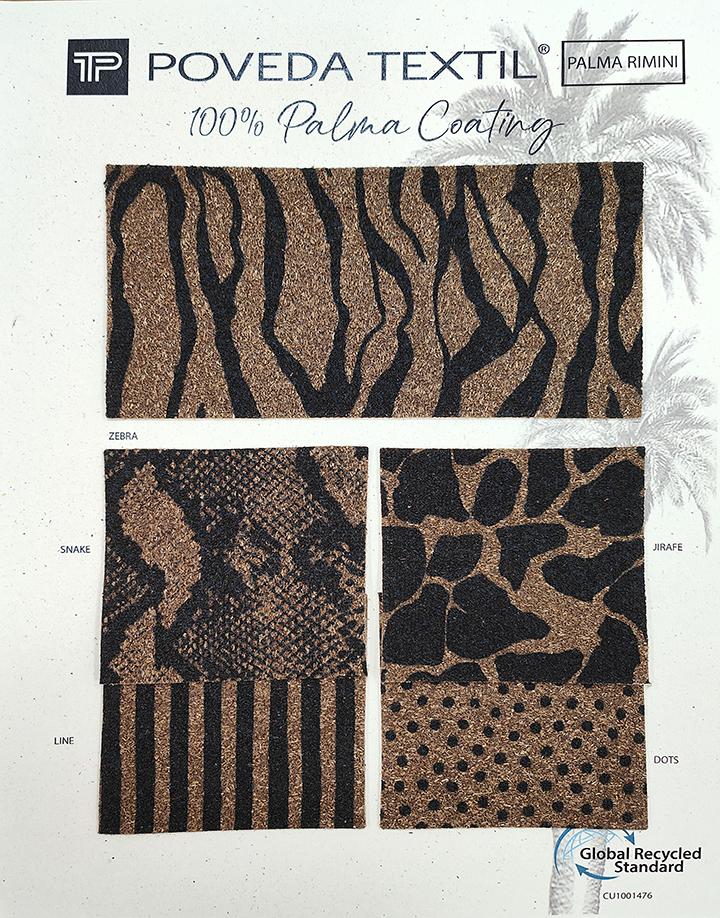

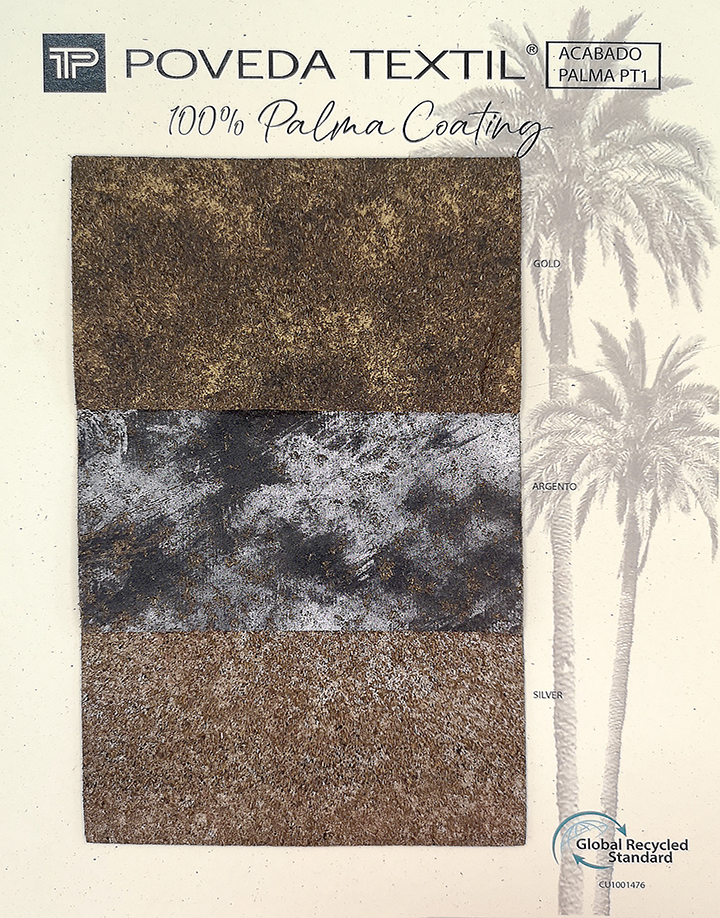

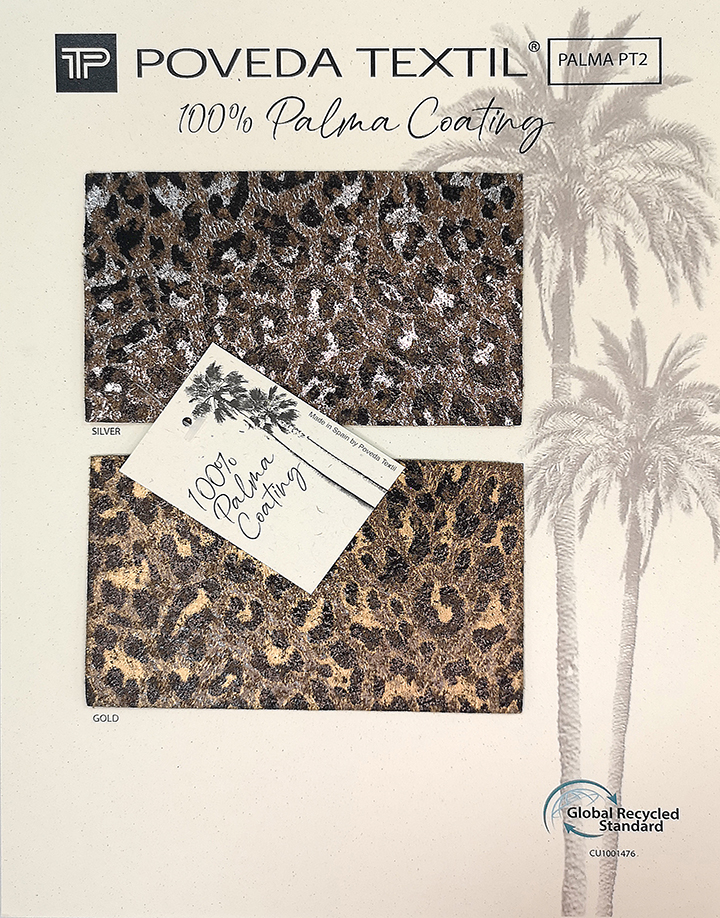

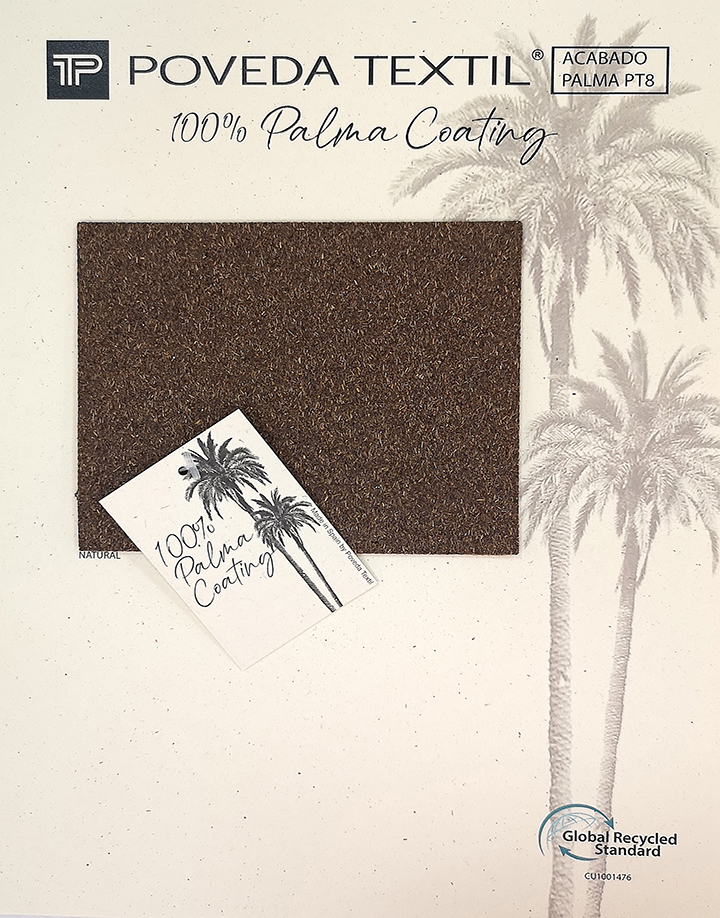

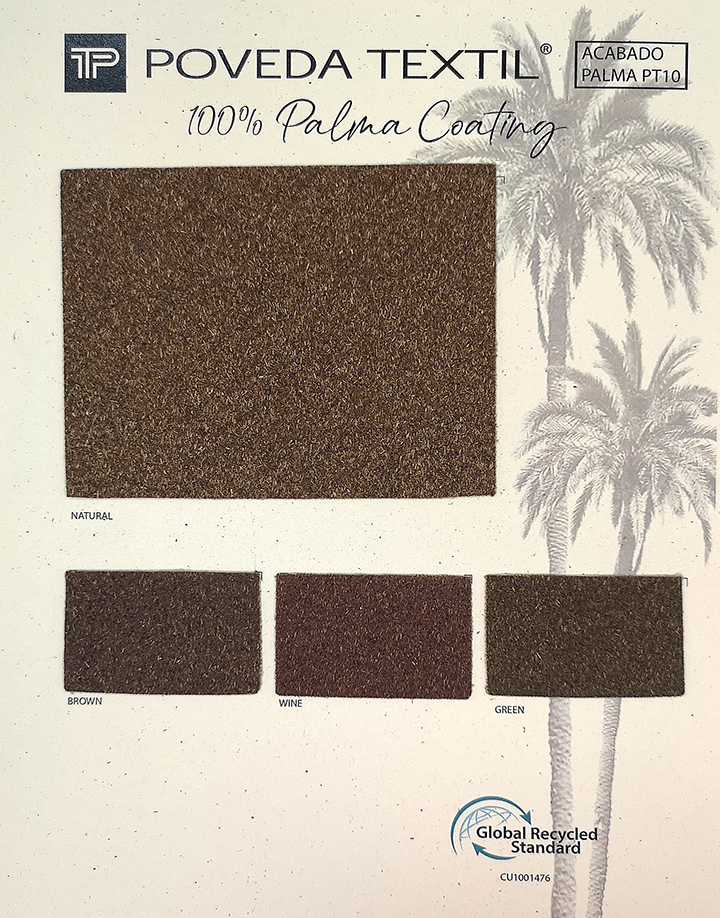

In Poveda Textil we have developed a fabric from pruning residues of the Alicante palm tree, using the latest technology in adhesives to create a 100% palm coating, which gives it an extremely natural look. We have different types of fabric, in different colors and designs, all certified as “GRS”.

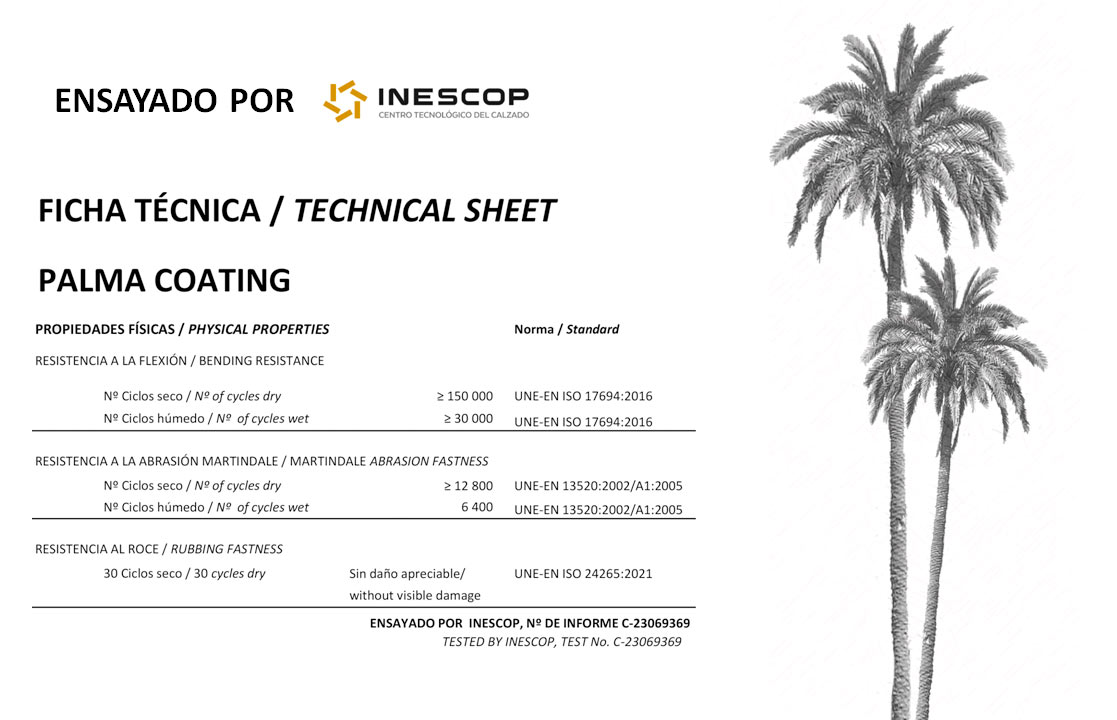

Thanks to this technology in adhesives and thermo-mechanical processes we have achieved a perfect product for the manufacture of shoes and bags. This fabric passes the abrasion and flexion tests as well as the chemical tests required by the companies, all with excellent results.

Focused on our commitment to sustainability and respect for the environment, we have created this new fabric by revaluing the remains of the Alicante palm tree. Consequently we preventing thousands of tonnes of waste from being incinerated, thus reducing more than one and a half million kilos of CO2 emitted by this practice, which is equivalent to 520 kg of CO2 per tonne of palm leaves.

Problem

Palm tree pruning produces annually 3,000 tons of remains, which leads to the emission of 520 kg of CO2 for each ton of palm.

Solution

With the collection or these remains, we have managed to reduce more than 1.5 million kilos of CO2 by avoiding the incineration of thousands of tons of waste.

Collection and shredding

Natural drying

Processing

Circular Economy and zero waste

We go one step further in the revaluation of palm residues as raw material and contribute to the circular economy and zero waste politics. Collecting companies manufacturing surplus, which remains during the production of their new products, we take advantage and use those leftovers to generate more recycled materials

Ciruclar Economy and zero waste

We go one step further in the revaluation of palm residues as raw material and contribute to the circular economy and zero waste politics. Collecting companies manufacturing surplus, which remains during the production of their new products, we take advantage and use those leftovers to generate more recycled materials.

Benefits

Social

We are reinforcing the sustainable usage of palm trees.

Economical

We are revaluating the remains of palm trees as raw material.

Environmental

We developed an environment friendly (biodegradable) material with multiple applications.

Our objective

To process the 3,000 tons of waste produced annually.